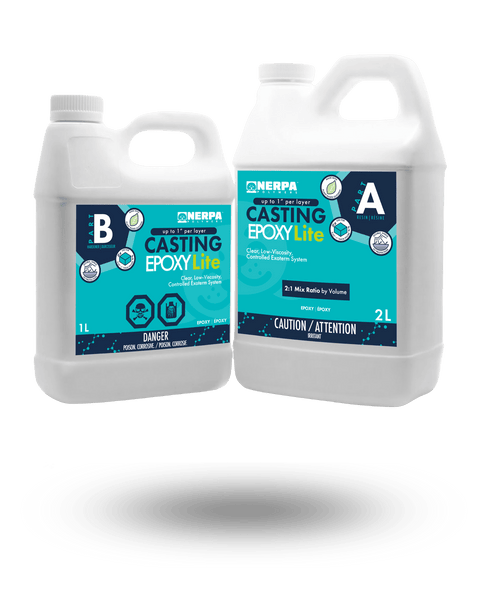

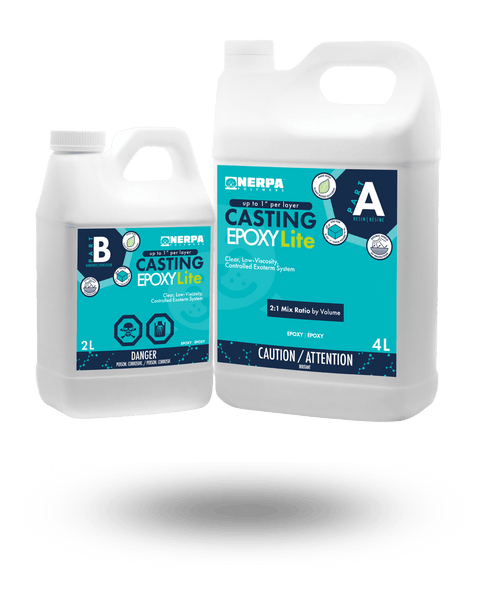

Specifically formulated for small projects with a maximum thickness of one inch, this novel epoxy resin system ensures optimal results while minimizing curing time. What sets this product apart is its unique viscosity reducer, made entirely of 100% bioglycerol-based molecules, resulting in a smoother and easier pouring process. With our Casting Epoxy Lite, your small projects were never easier to make!

One of the key features of this epoxy is its low viscosity, which ensures a smooth and consistent finish and makes it easy to work with. Additionally, low viscosity helps with air release during the curing process, resulting in a flawless and bubble-free final result. With a quick curing time of only 24 to 48 hours (depending on the total volume, the shape of the project and ambient conditions), it's perfect for those who want to get their projects done quickly.

Key features:

-

Low mixed viscosity for efficient air-release

- Colourimetry certification passed raw materials to ensure consistent optical clarity

- Shielded from rapid yellowing in sunlight through a two-stage complementary UV protection and usage of the components that do not absorb UV light

- Accelerator-free controlled cure delivers the best results without harmful additives

| Mixing Ratio |

2:1 by volume |

|

2.27:1 by weight |

| Appearance (mixed) |

clear, low-viscosity liquid |

| Intended application |

castings 0.25"-1" thick |

| Working temperature |

20-25°C

|

| Mixed Viscosity |

360-400 cP. |

| Working Time (1.0" thick 2L pour) |

60 min. |

| Pot Life (1.0" thick 2L pour)

|

4 h. |

| Set To Touch (1.0" thick 2L pour)

|

20 h. |

Ready For Sanding

|

24-48 h. (depending on the ambient conditions and thickness of the epoxy layer) |

| Hardness |

80+ Shore D |

| Bio-Content (resin) |

≥38% |

This Casting Epoxy Lite utilizes two-stage UV protection paired with the addition of components resistant to UV light exposure, ensuring that your projects will be protected from the sun's harmful rays and maintain their vibrant colour over time. The faster exothermic reaction of this epoxy is an advantage, allowing for a shorter curing time and quicker completion of your projects.